|

Wuhan Green world Technology Co., Ltd

|

tire crusher tire shredder tire recycling machine

| Payment Terms: | T/T |

| Place of Origin: | , China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

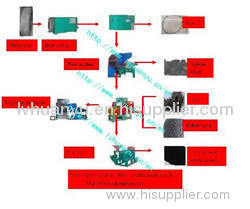

tire crusher,tire shredder,tire recycling machine

The production line technology of waste tire recycling developed by Wuhan Green world Technology Co., Ltd has these performance:

(1) The feed is whole tire.

(2) Fully automatic, no waste (dust, water, taste) Pollution;

(3) Steel wire, fiber are automatic separated;

(4) According to investor needs, the final product can reach 40 mesh ~ 120 mesh or 80 mesh ~ 120 mesh or 80 mesh ~ 200 mesh, stepless automatic sorting, product sifting rate to 93% or more (or in accordance with U.S. standards);

(5) High rubber powder purity , low fiber content ,less than 0.01% ;

(6) Power can be freely configured, complete or separate machine all can be customized.

(7) The scale of the automated production line can be: The annual handling capacity 3000 tons, 5000 tons, 10,000 tons, 20,000 tons.

The production line and process equipments are of precise structure, smoothly operation, and could separate three materials thoroughly: rubber, steel wire and nylon. To produce rubber granules with the granularity from 40 mesh ~ 120 mesh, 80 mesh ~ 120 mesh, 80 mesh ~ 200 (of which, 80 mesh ~ 200 mesh rubber powder technology is ourselves own, with which, according customer's demands, we can design waste tire recycling production line with the outputs are 80 mesh, 120 mesh, 150 mesh (the product is in accordance with U.S. standards) rubber powder, The production line technology of waste tire recycling developed by Wuhan Green world Technology Co., Ltd. is of no secondary waste Pollution (dust-free, tasteless, non-sewage), with low power consumption, high efficiency, it solves the environmental pollution, while opening up new ways for recycling waste tire for the shortage rubber market. Its core technology is in the international advanced level.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!